Evaluating Construction Worker Productivity

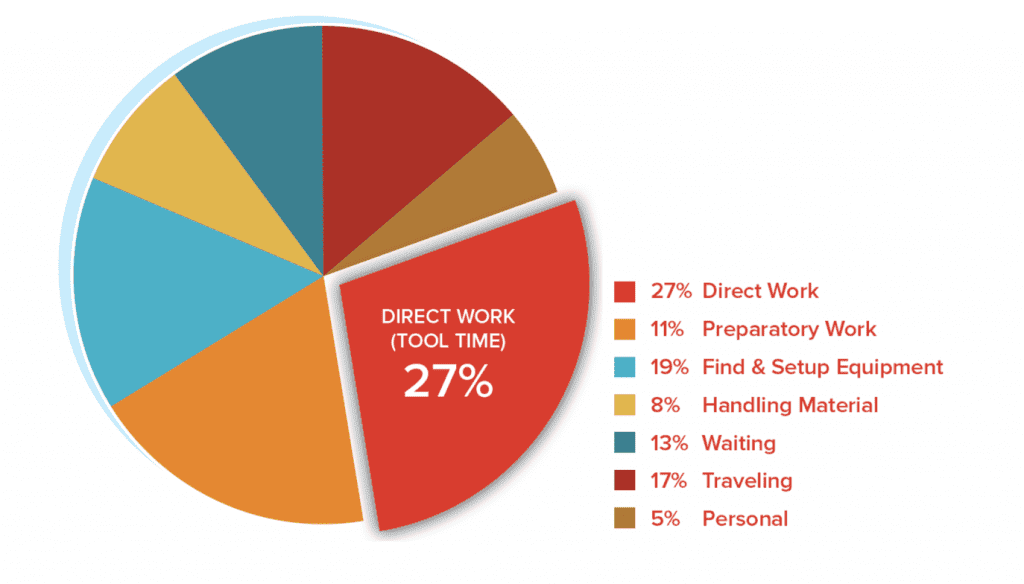

With construction labor accounting for 30% to 50% of a project’s total budget, keeping workers productive on value-added installation tasks is very important. However, as shown in industry third-party studies, the time workers spend on tools is only 50%1 for commercial buildings projects and only 27%2 for industrial projects (see the chart below).

This begs the question: How can construction projects best solve the problem of low productivity and make non-productive tasks into productive tasks, lowering the cost of the project and even decreasing the time to complete the project?

How a typical craft industrial construction worker spends their day

Can we improve productivity if we track workers?

Let’s first look at trying to improve construction worker productivity by knowing, to a more granular level, where the construction workers are spending their time, as the third-party studies did. If we are trying to reduce “traveling” time, tracking worker locations will help by learning how long crews spend away from the workface. Tracking will tell us how to strategically place tool cribs, washrooms, breakrooms, etc. to reduce overall travel time. However, some of the travel time will be difficult to eliminate.

We also need to look at the business value or return-on-investment of tracking workers to see if there might be lower hanging fruit to improve worker productivity. When we look at travel time, as studied by third-parties, the travel time for workers’ on a commercial project is 8%, while on an industrial project is higher at 17%. Intuitively, this makes sense since commercial projects cover less physical area. However, the cost to track workers in real-time is an expensive outlay with many fixed reader points where the return might be less than if we focus on the root problems of why workers need to move away from the workface. This brings us to thinking about attacking the non-productive time in a different way by considering material locations and availability.

Can we improve worker productivity another way?

The majority of the workforce wants to be productive, as there’s pride in one’s quality of work. It is difficult to be continuously motivated when the materials or tools are not available to complete the task at hand. Based on worker’s activities during the day, a significant part is spent on unproductive activities such as looking for materials or waiting, relating to 21% of a worker’s day in industrial construction and 24% in commercial construction.

The construction industry is among the least digitized3 industries where most process are recorded by hand and systems manually updated after the fact. Manual systems lead to errors and untimely data entry, and when put in context of construction materials this results in poor information on material availability and location, forcing workers to wait or wander around looking for those materials. This is a pretty ineffective way for a craft worker to spend their day when really they want to be productive and installing those materials.

If we look at solving this problem with better technology and process, the answer will lie in accurate, real-time information on materials, and repeatable work processes to assure the accuracy is kept high throughout the life of the project. Unfortunately, the legacy Enterprise Resource Planning (ERP) systems were built for the back office to process supply chain activities such as procuring materials and entering material receipt information to close out the payment for the vendors. However, ERP systems typically stop at those back-office tasks, and the information is available to only a select few office and project staff.

If we want to gain traction on eliminating non-productive tasks on construction sites, we need to give the field workers better tools and information on their materials to start and complete their installation work packages. Other industries have embraced technologies to improve worker productivity, including Web software, mobile apps, cloud hosting and identification sensor technologies, to name a few. If a craft worker could look up material status on required materials or even equipment, right in the field, without asking supervision, they could plan with higher certainty that their upcoming work could start and finish on time. This brings us to SiteSense® Web and Mobile Software for construction projects.

Is there a solution ready for construction?

Construction has begun to slowly adopt mobile technologies on construction sites, but part of the slow roll-out has been a lack of available applications that actually dramatically help workers on site. This is where SiteSense® shines. SiteSense® uses mobile technology that looks and feels like the everyday consumer apps workers are already familiar with but that focus on material management functions for the project site including the material receipt, storage and issue processes. SiteSense® takes care of what used to be paper-based processes and takes that step even further by allowing view-only users to access the material status, availability, and location storage information right from a worker’s tablet, phone, or PC.

Additionally, the work process and access to material information can be easily augmented with automation technologies including barcode and Radio Frequency Identification (RFID) to reduce or eliminate human interaction, providing even higher levels of accuracy through proper identification and current location for materials. SiteSense® integrates with these technologies seamlessly and through smart infrastructure, the cost to implement the technology on a project today is magnitudes less (while much more accurate) than systems from 5 to 10 years ago.

Additionally, the work process and access to material information can be easily augmented with automation technologies including barcode and Radio Frequency Identification (RFID) to reduce or eliminate human interaction, providing even higher levels of accuracy through proper identification and current location for materials. SiteSense® integrates with these technologies seamlessly and through smart infrastructure, the cost to implement the technology on a project today is magnitudes less (while much more accurate) than systems from 5 to 10 years ago.

Contact Intelliwave today to learn more about implementing project site tools for site materials management and see how quickly worker productivity can increase on your projects.

- Hewage, CJCE

- CII IR 252-2A (2010), Craft Productivity Study

- Imagining construction’s digital future, Agarwal, McKinsey