Choosing the “best fit” technology to facilitate your material tracking needs can be overwhelming. Often when selecting a tracking technology, there are compromises which at first are not apparent but surface later in the project often when it is too late. With project materials accounting for 30% to 70% of total installed cost of a typical construction project, the stakes couldn’t be higher. Selecting the right technologies for accurate material management and tracking is crucial for project success.

Selecting between Radio Frequency Identification (RFID) and barcode technologies can be confusing due to the complexity and wide feature set for both technologies. Despite many industry case studies on both technologies, selecting the right technology for your application is not always straightforward. Both RFID and barcode tracking technologies have advantages and limitations depending on the application. As such, SiteSense® Materials Management Software seamlessly supports both technologies. Intelliwave recommends implementing a hybrid tagging approach using both Barcodes and Active RFID technologies to leverage the strengths of both technologies while minimizing weaknesses.

Barcodes are a great low-cost option for material and asset identification, allowing for error-free identification and automated data entry into inventory and warehousing system. With that being said, scanning barcodes requires “line-of sight”, similar to passive RFID labels, it becomes very difficult to automate location movement over large, dynamic and ever-evolving construction site. This means multiple manual “scan” actions are required throughout the lifecycle of the material (from vendor to installation) in order to update material location and status information.

We’ve compiled 5 rules to help you select the “best-fit” Track and Trace technologies.

Rule #1 – Planning increases worker safety and morale

Safety begins with planning. Both RFID and barcode systems paired with SiteSense® Materials Management System, allows the user to effectively plan their work, making the construction workers safe and efficient while locating material.

Having up to date material locations result in a safer site, higher worker productivity, and ultimately increases the crew’s morale. This means that workers can proactively locate material, identifying the area they will be working in, allowing them to accurately plan their day. While barcodes provide locations based on a last “scan” event, RFID systems will automatically re-locate materials that have been moved, even without someone scanning the item.

Rule #2 – Inventory identification is crucial for inbound and outbound activities

Throughout the course of the project, material will have both an inbound and outbound transaction. Entry and selection errors during these activities are costly. If the wrong material is selected due to improper identification, the consequences can be costly.

Both barcode and RFID, solve these issues by providing a machine-readable layer of identification. When combined with SiteSense®, extra details and ship-loose components, that otherwise might be lost, are easily tracked.

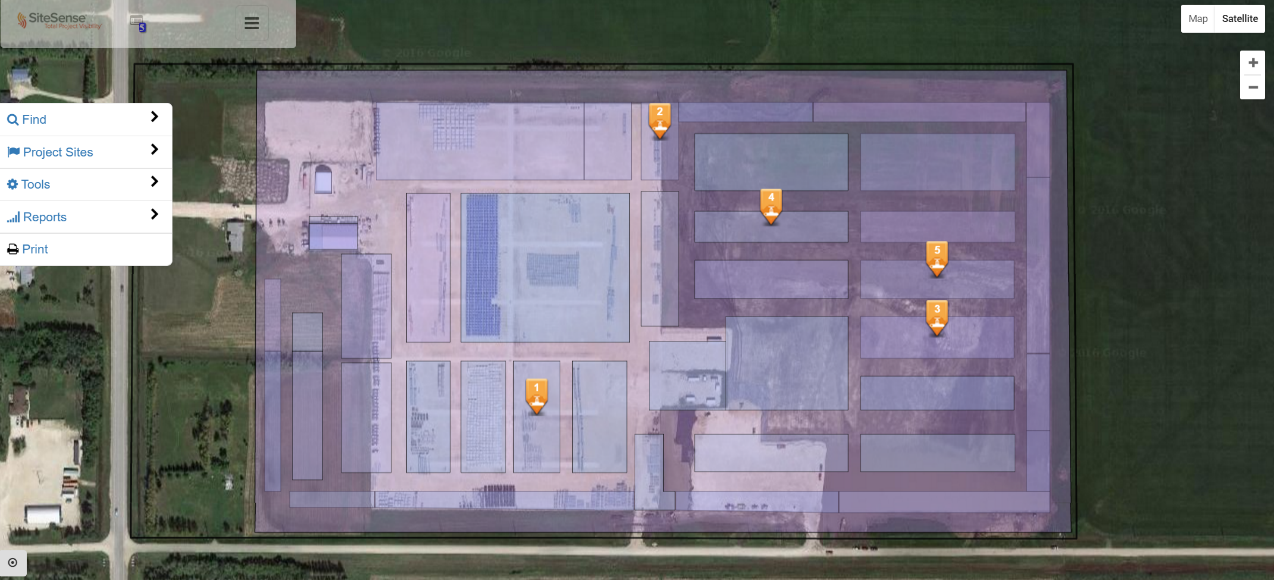

Rule #3 – Real-time project visibility delivers immediate results

Laydowns and warehouses are complex environments. Material is shuffled throughout the yard and warehouse multiple times throughout the day.

While barcoded items require continuous scanning at various stages and events, RFID allows for autonomous status updates. Users now know when material enters ‘Inspection’ or ‘Quarantine’ zones and can be updated nearly instantly. There’s no need to wait on status messages from the field or for paperwork to be processed with this level of automation.

Rule #4 – Inventory locations are never static

With the frequency of material moving around the site, it is often very difficult discern where your material is currently located on a project construction site. This is especially true during hectic construction hours when standardized procedures may not be followed when moving or handling material. Consider a common scenario where a forklift operator is under pressure to deliver many pieces of material to the construction team. Many materials will need to be moved to gain access to the requested material. However, after picking the material, the operator moves on to the next piece of requested material, but does not document the new storage location of moved material.

Rule #5 – Reduced time spent cycle counting inventory increases productivity and accuracy

The overwhelming task of counting inventory is not for the faint of heart. Human error leads to inventory errors requiring additional cost for re-counting and reconciling the errors.

Barcoded items are placed into storage areas with barcode being visible. To scan the barcode, workers must be within a few feet of the material. While scanning barcodes for cycle counting is more efficient then manual, paper-based processes, it is repetitive and time-consuming.

Choosing the correct technology for your project can reduce time and cost associated with material operations. In most cases, a hybrid tagging approach is adopted whereby project critical materials are tracked with active RFID tags and the bulk or commodity items are barcoded. This hybrid approach reduces both the operational and upfront cost of the system deployment. Contact Intelliwave to help get your project up and running with an automated (and identifiable) materials management system.