Plant maintenance and turnarounds are complex and expensive activities. Turnarounds are maintenance activities performed on refineries, chemical facilities, power generation plants or other industrial facilities where sections of the facility are shut-down. With a typical turnaround lasting between 20 to 60 days, any delays in the schedule can have a negative effect on the plant’s performance. For a successful turnaround, proper planning is critical to ensure quality and safety are maintained throughout the maintenance and construction activities. If either of these factors are neglected, the turnaround schedule could be delayed or could lead to unplanned shutdowns after start-up.

Turnarounds are complex, labor-intensive activities with the number of workers onsite typically peaking at 4 to 5 times the operational staff of the facility. This quick increase in activity on site is difficult to manage, especially given the large number of workers not familiar with the facility. However, for the project to be successful, turnaround managers and stakeholders need accurate, timely information on work progress to make informed decisions and mitigate potential risks to ensure the project schedule is unaffected and the facility is shut down for the shortest period of time.

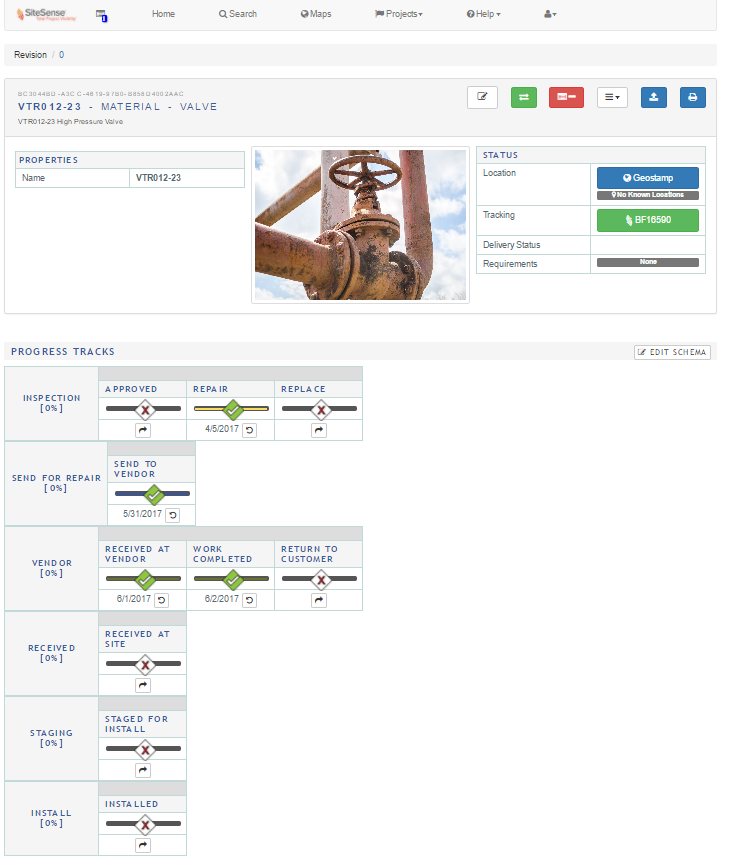

SiteSense® allows managers to track and monitor the progress of materials and tagged equipment throughout the turnaround life-cycle with an easy to use cloud-based system. To cut through the fog of work, SiteSense® uses Progress Tracks combined with mobile technology to update and track the material and equipment maintenance cycle in real-time.

Every flange, spool, valve, pump and any other materials or assets involved in the turnaround are tracked through an individual profile (an example shown in the picture below). On this profile, pictures, documents, and comments allow the turnaround team to track progress and identify any unforeseen circumstances. Each piece of material is paired with a rugged barcode or RFID tag allowing the user to quickly identify the material in SiteSense, revealing its status. Progress Tracks are assigned to the piece of material based on the material’s life-cycle during the turnaround which are updated by workers in the field using mobile devices. As the resource undergoes each stage of the maintenance process, Progress Tracks are completed identifying the five “W’s”:

- Who did the work

- What work was done

- When the work was completed

- Where the work was completed

- Why the work was required

As shown in the photo below, it was decided that the valve in question needed to be repaired by an external vendor and the progress tracks are updated as the valve moves through the repair process giving the turnaround team full visibility throughout this process.

SiteSense® enables you to identify and track your progress, arming you with a set of tools to make you more productive and organized in the turnaround process. SiteSense® progress tracks also helps maintain quality and safety throughout the turnaround. With each step in the maintenance process being monitored and enforced using progress tracks, managers can ensure that the appropriate quality checks and processes have been followed along the way. Data across all turnaround materials is then analyzed using powerful SiteSense® reporting tools, this allows managers and stakeholders to view reports on vendor performance, turnaround progress, as well as identify any key performance indicators which may be threatening productivity during the turnaround process.

Do you have a turnaround or shutdown coming up? Contact Intelliwave today to boost your productivity to the next level with the use of SiteSense® cloud based software.