A Highly Productive Construction Project is a Safer Project

When construction projects are highly productive, there is typically a direct correlation with lower than normal reported safety incidents. This article will discuss tools and best practices that can reduce safety incidents by utilizing solutions that are geared towards improving worker productivity. Let’s dive into this a bit deeper to find out more.

Software Solutions Geared to Improving Worker Productivity

With the arrival of modern mobile devices (think tablets and smartphones) into our everyday personal and business use, industry has been quick to adopt the technology as a means of improving their productivity. However, construction has been slower than other industries to embrace the full use of mobile devices. There are bright spots with some leading contractors widely adopting mobile devices, leading us to believe widespread use of mobile devices on all project sites will just be a matter of time. Part of that adoption pickup requires the “killer app” for the devices to be ultra useful in daily construction tasks.

At Intelliwave, our cloud and mobile-based solution called SiteSense®, gives workers the information they need about their most critical resources to complete installation work, including material information (locations and quantities, for example), tools and equipment information and even crew information. The productivity benefit is two-fold for the construction project:

- Planning is based on actual availability of resources (real-time constraint analysis)

- Construction execution on installation work packages or tasks finish ahead of schedule as all materials and resources were confirmed to be available prior to starting work

The Productivity Correlation to Safety

Prior to technology aiding the workforce to work more effectively, inefficient manual processes were used.

Work Process Prior to Construction Mobile Technology Solutions

Without the technology to digitally track the location of materials, the workers would typically record the temporary storage location of the material on a clipboard and hand that into the office where the storage location would be updated manually by an office worker in a spreadsheet or database. Those storage locations could be warehouse bin locations, building room locations or outdoor yard areas. The accuracy and timing of the data entry depends on the workload of both the crew and the office staff, as well as, correct entry. For projects that are fast paced and/or understaffed, this data might not always be recorded, thus the accuracy and completeness of the data is typically low.

When the material is requested for installation, the job of the crew to find and pick that material can become like a game of find the needle in the haystack. Similar but different materials often look exactly alike and in the case of finding unique materials (engineered for the facility), this task to find and pick the correct materials can be extremely difficult. The longer workers search for materials, the greater their exposure to the hustle of the construction site areas (potentially increasing the risk of a contact with a machine, as an example) and the more workers are exposed to potential trip hazards as they step over materials searching for the right one. Keeping the workers in the field for longer than necessary has resulted in more hand and wrist injuries by workers slipping or tripping on materials during the search.

Enhanced Work Process with Construction Mobile Technology Solutions

When construction focused software applications, such as SiteSense®, are introduced into the work process, these safety incidents described earlier can be avoided. With accurate information for the workers on the exact location of the material required for picking, the workers can go directly to that material, and not spend a minute longer searching, thus reducing risk to a safety incident. The end result of the introduction of SiteSense® has vastly improved productivity (both the indirect labor to pick the material and the direct labor to install the material by reducing wait time) while also reducing the chance of safety incidents during the search task.

Safety Considerations Implementing Mobile Technology

While both productivity and safety can be improved with the implementation of mobile devices on construction sites, training and work procedures must be employed to create a culture of safe use for the mobile technology. As we all know, distracted driving by the use of mobile devices is an ongoing safety issue. The same principles apply to the use of mobile devices on project sites. Safe practices must be followed, or the result could easily be bodily harm. An example of training and preparing workers for using mobile devices on project sites include safe practices such as stopping and visually ensuring the surrounding area is safe prior to use of the mobile device (essentially, keeping out of harms way). And only continue on once the mobile device operation is completed.

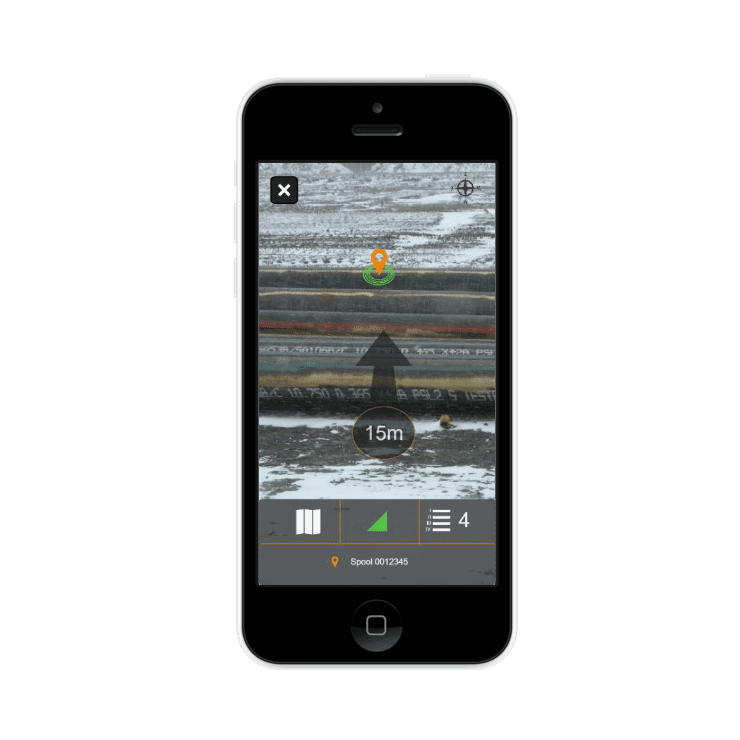

At Intelliwave, we have taken the task to be one step ahead of human tendencies to look down at the mobile device, by integrating augmented reality into the “search” function of our mobile applications. Instead of a worker looking down at the mobile device for map-based search activities, the worker can hold the device up in front of them to scan the horizon, showing the worker the direction and distance to walk (or drive) to the material required for picking. This is ultimately helpful for the worker in the event there could be a machine or object in harms way.

Final Thoughts

Safety doesn’t need to be compromised when making a project more productive. Increasing productivity improves site safety when implemented with the right technology and work process changes. Contact us at Intelliwave to find out more and be a part of the construction revolution to improve productivity!