Materials Management does not begin when materials and equipment arrive at the fab shop, job site or warehouse. A robust materials management program starts when Engineering begins to define equipment in the engineering modeling and design construction work packages using various software tools.

Once the engineering stage has begun, the materials management group must gather various pieces of information together when developing a material management strategy. These include, but are not limited to, project number, battery limit table, material type table and unique site serial numbers. The material management team must also consider the end client’s naming conventions and specification requirements when developing the structure and nature of the equipment tagging philosophy along with the bulk material codes to be used on the project.

Tags are defined as unique nomenclature values for Equipment that will have a predetermined location in the plant and typically have a Unit of Measure (UOM) of Each. Using the project numbering schema it becomes quite easy to determine where the equipment is to be installed, what type of equipment it is and if any similar pieces of equipment exist throughout the facility. The tagging and description definitions are critical for tracking certifications, testing, and inspections during construction. This also becomes extremely important when construction is completed and turnover packages, commissioning, operations and maintenance activities have begun.

Commodity codes, commonly referred to as “Bulks”, are defined as multi-use items and can be located anywhere in the facility as defined in the modeling software. Bulks cover a wide variety of items such as steel, piping, cable, valves, electrical components, accessories, and fittings. Selecting which units of measure will be used with specific bulks is critical to ensuring the associated materials can be tracked efficiently and accurately. With multiple possibilities existing for many materials, the UOM must be defined early and applied consistently throughout the project (i.e. feet or meters, inches or millimeters, kilograms or pounds). Ultimately, a discussion is necessary to determine how best to manage these materials and consideration must be given to how the material will be called-out by the construction team. The use of “Lot” as a UOM should be avoided as there is absolutely no indication of how to quantify or determine what materials the project will be receiving using this type of UOM.

Defining a consistent Materials Management structure and incorporating such things as disciplines, battery limits, work areas, module groups, equipment types, UOM’s, etc. into the project part numbering system has several advantages:

- A proper naming convention aids in determining the delivery point of equipment and materials based on the project strategy and construction plan.

- A proper naming convention along with the project schedule also helps to determine when equipment and materials are required by construction for installation or fabrication.

- At the various stages of engineering review, a well-defined part numbering system provides a consistent interface between project groups such as Field Construction, Project Controls, Procurement, and Quality.

Engaging Materials Management teams early in the engineering phase of a project ensures visible tracking of materials and equipment through the entire project life-cycle. From material requisitioning to procurement on to delivery, and preservation phases, ending with the final stages of installation, commissioning, and operations. For full visibility, it is not only important to implement a Material Management strategy for major equipment and bulks but also for sub-component parts, ship loose items and spares.

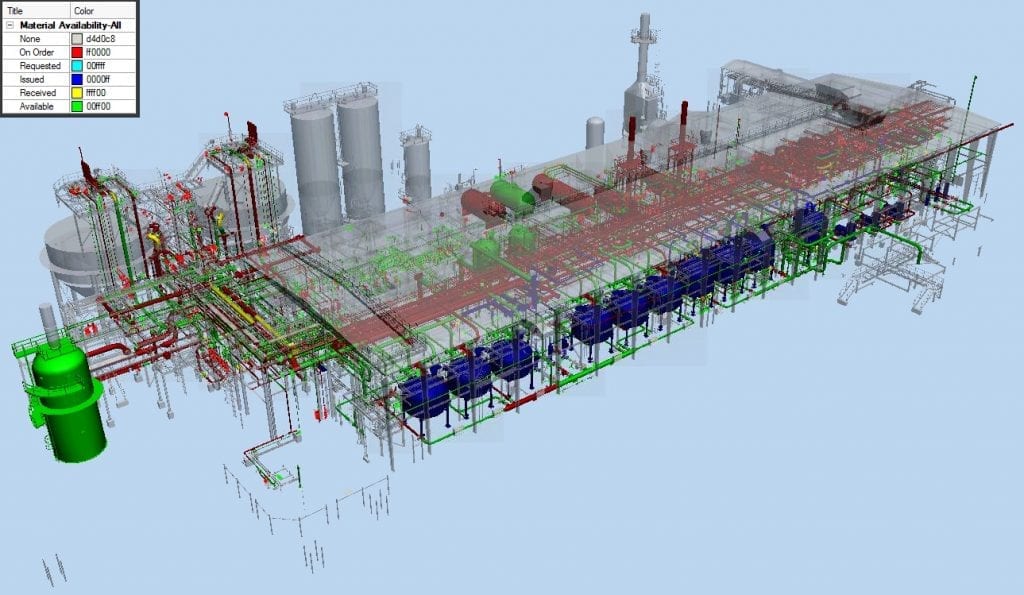

With an effective part numbering system that has been developed through the engineering phase of a project, project progress can easily and accurately be measured as consistent nomenclature for materials is used throughout the project. Overall procurement progress is measured from the interface with the engineering design tools and the material management system. To determine the overall procurement progress, actual material procured is compared against the total material requirement in the model and the project schedule. Likewise, actual construction completion is measured against the engineering model and schedule to evaluate the overall construction progress.

Contact Intelliwave today to assist you with the Site Materials Management setup and interfaces required for a successful project.