Electrical cable is an essential material for construction projects and is generally met with great difficulty when trying to manage the various cable types, reel lengths, and construction areas involved during installation. Cabling is the veins and the arteries of all major factories, refineries, plants, and production lines. Large construction projects can have hundreds if not thousands of kilometers of cabling material as well as vast numbers of individual reels to keep track of. Properly managing electrical cable during the construction phase is critical to project success.

Successfully managing cable has two primary challenges:

- Cable is delivered in exact lengths, sometimes broken over multiple reels, to a job site. These reels will arrive with a pre-determined length based on an engineering cable schedule for the project. This means that each length of cable and reel have to be carefully tracked and managed to avoid costly re-ordering.

- Electrical cable is a unique material as the vendors that deliver it to the job site on reels will sometimes require the empty reel to be returned to them within an agreed upon timeline from the supply contract. Failure to return the reels typically results in penalties from the cable vendor adding unforeseen costs to the project. Consider one example project where the client paid a $0.47 per meter of cable deposit for the reels on which the cable was delivered. While this number may seem inconsequential, the project had ordered 792 kilometers of cable. This would amount to a total deposit for cable reels on the project to almost $375,000. These numbers certainly help to represent the importance of properly managing and tracking cable reels on a construction project.

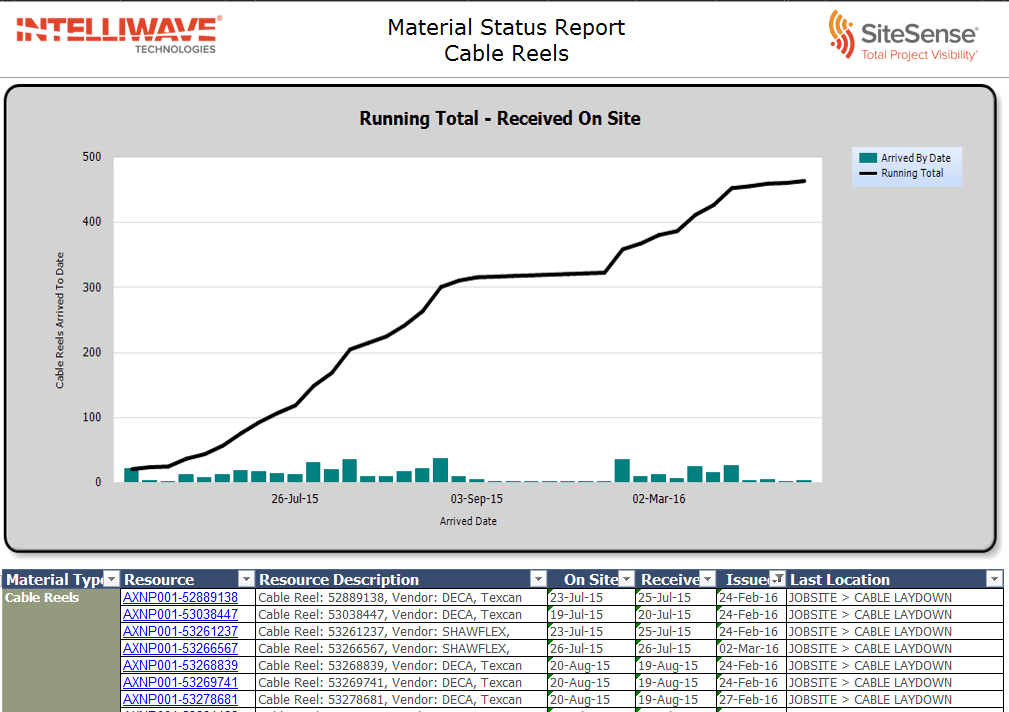

Material managers must preserve and keep track of the cable reels, as well as allowing the construction team access to them in a timely manner so they do not affect the construction schedule. Without an appropriate tool available, the task of managing both the cable and the reels can be overwhelming. SiteSense® was developed with cable reel management and tracking in mind. SiteSense® not only allows users to track the physical location of the cable reel but at the same time also manages the quantity issued to the workface from that specific cable reel. This gives construction teams up to the minute inventory quantities when they need it most.

What makes SiteSense® a powerful tool for cable and reel management?

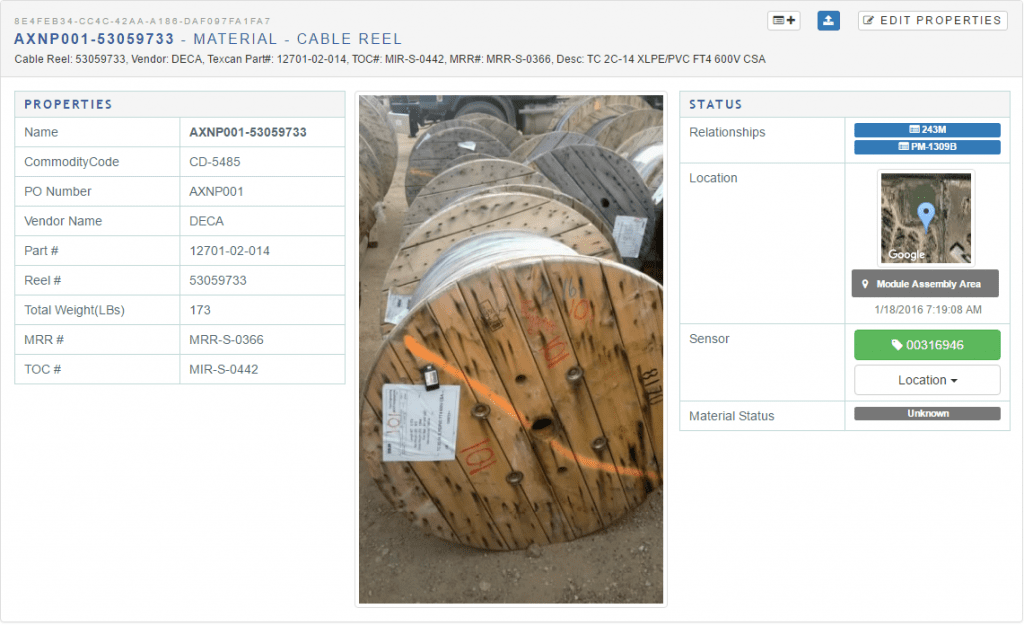

SiteSense® uses an innovative parent-to-child (Cable Reel-to-Cable) relationship combined with active RFID (Radio Frequency Identification) locating technology to track both the cable material and individual reels in the field. By attaching an active RFID tag to the cable reel when it arrives at the project site, the reel’s location is tracked regardless of where it is moved to on the job site, allowing field users to easily locate it.

As an additional layer of functionality, SiteSense® also allows users to account for each pull of cable on the reel accurately and efficiently. Using SiteSense® Material Management software, mobile users can request and issue lengths of cable from specific reels to the construction workface as needed using a tablet device. Not only does this create a more efficient request and issue process for cable, but it allows the reel to remain at the workface, improving the electrical worker’s productivity, without losing visibility of the remaining cable quantities and the reel’s location.

Finally, the powerful reporting tools within SiteSense® are used to determine which cable reels are empty and are ready to be returned to the vendor. When it comes time to return the empty reels to the vendor, a worker must simply look up its current location on the SiteSense® map, and retrieve it from the field for loading.

As illustrated above, cable and reel management is complex but essential to the success of any project. However, using a tool like SiteSense® to manage cable, along with other materials, will simplify the task and improve visibility for your construction project.