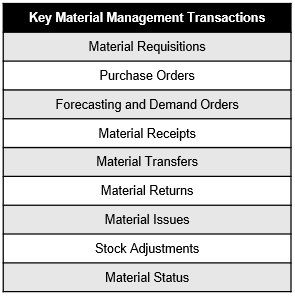

When it comes to managing construction materials, there are a few key material transactional process steps that are required for crews to perform in order to keep accurate and timely status of each material piece. Each of these material transactional process steps (also referred to as material movements in some cases) are important to maintain visibility of the material pieces from production to installation, ultimately to provide the construction work crews with the right materials ready at the right time, maximizing their productivity to reduce the project’s capital cost. Below are the key material transactions required for project success:

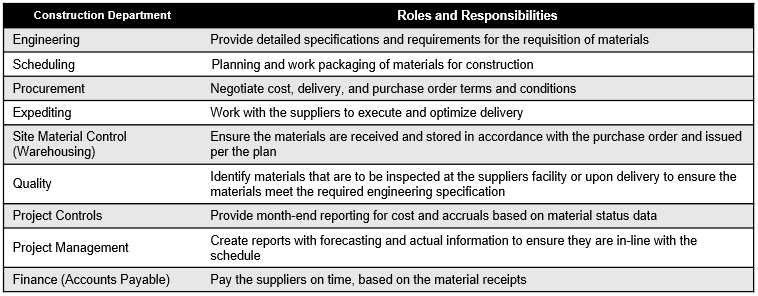

The construction company executing the project needs to have the key material transactions above to be completed accurately and timely in order for each department to be successful. When each department completes their work, the construction project has a much better chance at being on time and budget. Below are some of the material transaction roles and responsibilities required to be completed and made visible by each department, for further processing by other departments.

Even with all the inter-related dependencies listed above, some construction companies still believe a spreadsheet is the best way to manage these transactions. Usually that decision was based on a false assumption that because spreadsheet software is effectively free, then the cost is going to be lower than using more expensive software that was developed specifically for materials management. The end result of using spreadsheets to manage materials inevitably ends up costing the project way more in delays and labor hours, trumping the cost of an actual built-for-purpose software system.

Here are 7 common problems encountered when a spreadsheet is utilized for material transactions:

- Only one user can update the spreadsheet at a time

- Entering data manually leads to errors and inaccuracy

- The spreadsheet becomes too large to manage, has too many macros and eventually becomes unusable due to sheer size and broken links

- The material transactions are not in real-time and are end up being captured days or weeks later

- Historical data is difficult to analyze

- Material cannot be forecasted or automatically allocated to work packages

- Construction departments cannot do their jobs effectively

Even though today’s spreadsheets have become feature rich, they were not designed to manage the complexity or material transactions for construction projects.

The good news is that there are commercially available software systems that were developed exactly to solve this complex problem for construction projects. Intelliwave’s SiteSense® Materials Management Software can easily define, maintain, and monitor the data as well as automatically Track and Trace materials using web, mobile, and sensors (e.g. barcode, RFID and GPS technologies) to ensure accurate project reporting for construction and management teams.

Contact Intelliwave for more information to help transform your project from a mess of spreadsheets to a purpose-built construction based software system.